LANGUAGE

Kitchen Room

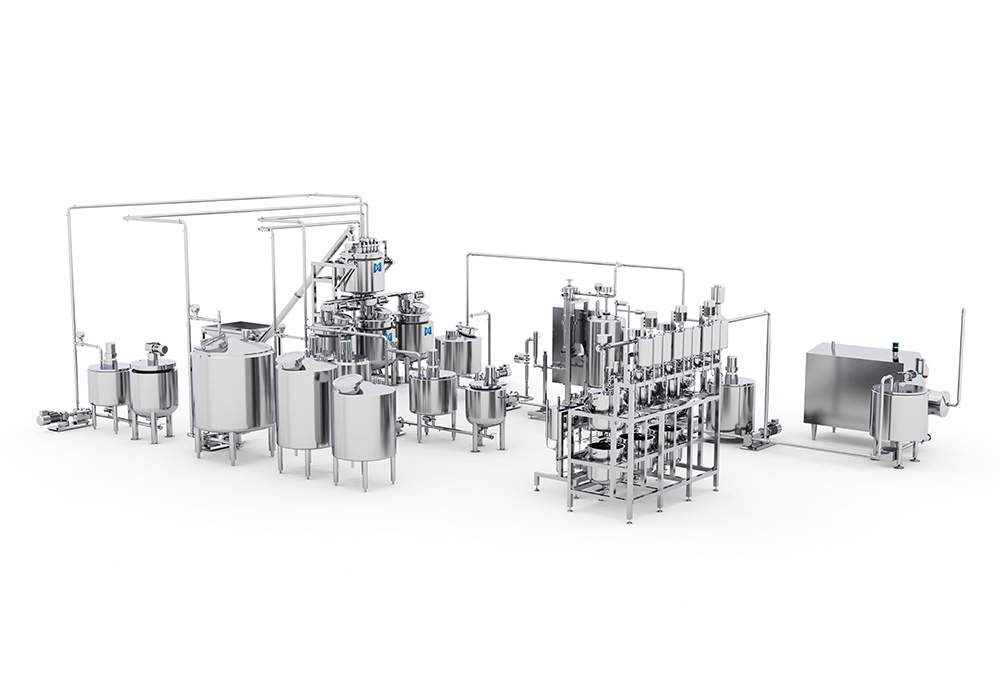

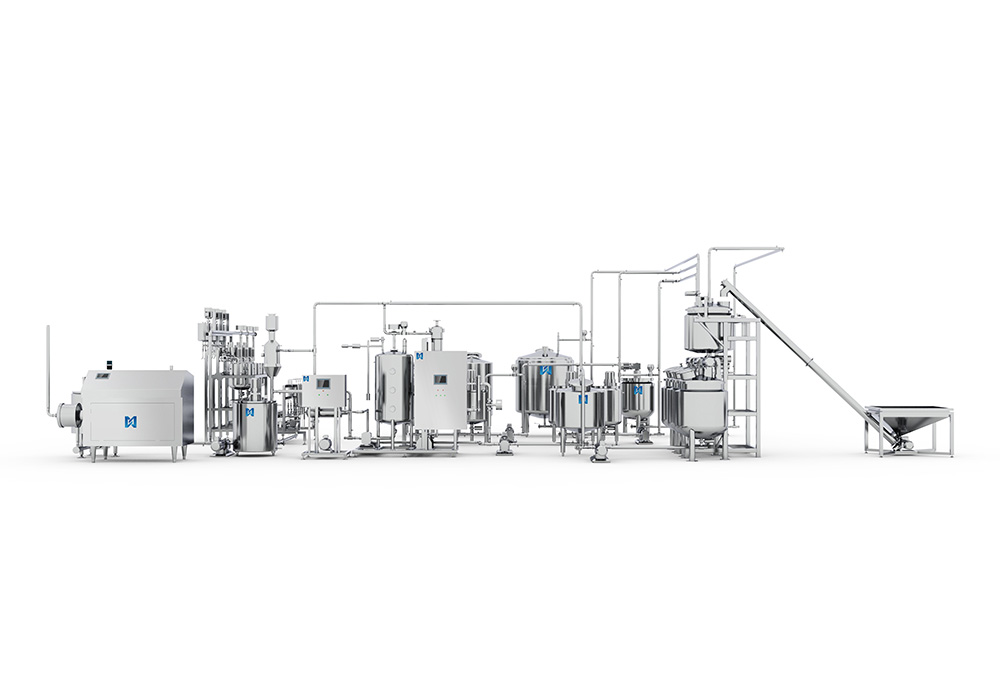

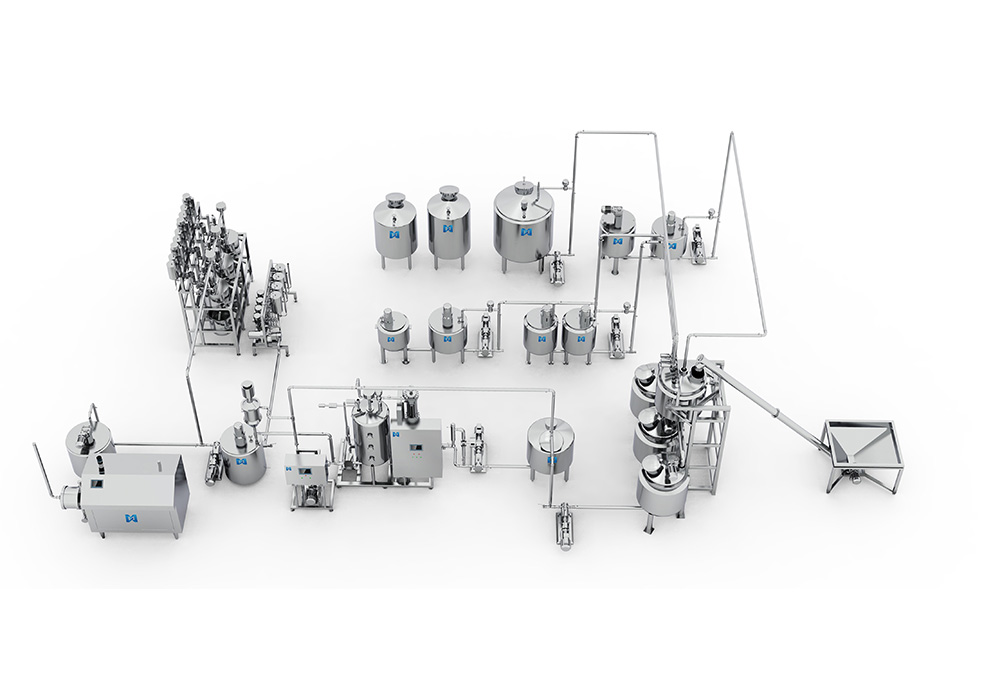

Sugar liquor(white granulated sugar,syrup) is fully dissolved in sugar dissolver.after fully dissolved in gelatin dissolver according to different recipes,the gelatin liquor or starch is added into sugar dissolver.after a full mixture,the sugar liquor is pumped by cam pump into mixing pot to be completely blended with the gelatin liquor.

Later, the sugar liquor is pumped by cam pump into the snakelike heating tube at a fixed quantity,the from pipe coil infusion machine is heated to maintain internal steam pressure at 7-8kg,thus the materials inside the tube heated partially vaporize through heat exchange. The materials are then moved through the upper end of the snakelike tube into vacuum presser kettle whose inner pressure intensity is 0.6-0.7bar. the negative pressure allows the materials to boil and vaporize so as to increase the sugar content by extracting moisture and bubbles.

To improve transparency,and to reduce the destructive effect of high temperature on gelation,then,the sugar liquor is pumped by the cam pump into the compounding pot where is goes through the compounding process of color,aroma,tartness and is then poured into the molding pot.the whole consecutive vacuum sugar ook process only requires 4 minutes.

Later, the sugar liquor is pumped by cam pump into the snakelike heating tube at a fixed quantity,the from pipe coil infusion machine is heated to maintain internal steam pressure at 7-8kg,thus the materials inside the tube heated partially vaporize through heat exchange. The materials are then moved through the upper end of the snakelike tube into vacuum presser kettle whose inner pressure intensity is 0.6-0.7bar. the negative pressure allows the materials to boil and vaporize so as to increase the sugar content by extracting moisture and bubbles.

To improve transparency,and to reduce the destructive effect of high temperature on gelation,then,the sugar liquor is pumped by the cam pump into the compounding pot where is goes through the compounding process of color,aroma,tartness and is then poured into the molding pot.the whole consecutive vacuum sugar ook process only requires 4 minutes.

For more information, please email or call our 24-hour hotline.

- cali@huadongcn.com

- +86-13429390286

Copyright ©2026 Ningbo Huadong Machinery Co., Ltd. All Rights Reserved.